Artificial intelligence (AI) is rapidly transforming the world we live in, and the field of quality control is no exception. With the ability to process and analyze vast amounts of data, AI is becoming an increasingly valuable tool for improving the quality of products and services across a wide range of industries. From detecting defects in manufacturing processes to identifying potential errors in software code, AI helps to improve quality control processes and enhancing efficiency. In this article, we will explore how artificial intelligence is transforming traditional functional tests, manual quality testing and the various ways it is being implemented in different industries.

What Is AI In Quality Control And How Does It Work?

AI-based inspection systems can perform detailed and accurate inspections in real time, reducing the need for manual labor and minimizing human error. With the use of deep learning algorithms and machine learning techniques, AI can identify defects and provide valuable insights that can help businesses achieve higher levels of product quality and customer satisfaction.

Here’s How AI In Quality Control Works:

Data Collection

AI plays a critical role in collecting and processing data for quality control. By collecting real-time data from sensors and other sources, AI can enable manufacturers to identify and address potential quality issues before they become significant problems. Additionally, AI can help automate the data collection process, freeing up resources and allowing for more precise data.

Data Analysis

AI can analyze vast amounts of data to identify patterns and anomalies that are difficult for humans to detect. This helps teams to detect potential issues early, making it easier to address them before they escalate. AI-based analysis also helps to identify areas where improvements can be made to enhance the overall quality of products.

Quality Prediction

AI can predict the quality of a product based on data collected during the manufacturing process. By using predictive analytics, AI algorithms can anticipate potential defects and prevent them from occurring, which can help to improve overall product quality and reduce waste.

Quality Inspection

AI-based inspection systems can automate the inspection process, ensuring that every product is thoroughly examined and meeting quality standards. With AI, manufacturers can conduct inspections at a much faster rate while still maintaining the same level of quality control.

Continuous Improvement

AI can help manufacturers to identify areas of improvement and optimize production processes. By analyzing data collected during the manufacturing process, AI can identify areas for improvement and make suggestions for changes that can enhance overall quality and efficiency. By continuously monitoring and adjusting production processes, manufacturers can maintain high levels of quality and keep up with changing customer needs.

What Are The 4 Types Of Quality Control?

Quality control is an essential aspect of ensuring that products and services meet or exceed customer expectations. It is a process that involves monitoring and testing the product or service throughout its development and production optimization to ensure that it meets the desired quality standards. Production system of software consists of four stages:

Pre-inspection

Pre-inspection is the process of inspecting materials or components before they are used in the manufacturing process. It is essential in identifying defects or issues that may impact the quality of the finished product. Pre-inspection helps to ensure that only high-quality materials are used, which ultimately improves the overall quality of the final product.

Inspection During Production

Inspection during production involves checking products at various stages of the manufacturing process.It helps to detect potential issues early on, allowing manufacturers to address them before they escalate. Inspection during production also ensures that products meet quality standards and are consistent throughout the production process.

Final Inspection

Final inspection is the last step in the quality assurance process and involves a thorough check of the finished product. It is is essential in ensuring that the product meets all of the required quality standards before it is shipped to customers. Final inspection typically involves a visual inspection, measurement and testing, and documentation of results.

Post-Delivery Inspection

Post-delivery inspection is the process of inspecting products after they have been delivered to customers.It is important in identifying any issues that may have occurred during shipping or that may have been missed during earlier inspections. Post-delivery inspection helps QA teams to identify potential quality issues and make improvements to their products and processes to prevent them from occurring in the future.

Examples Of Artificial Intelligence Applications In Quality Control

Quality Control Of Industrial Products

Artificial intelligence is increasingly used to improve quality assurance of industrial products, such as machinery and electronic components. AI-based inspection systems can identify defects in real-time, allowing manufacturers to detect potential quality issues early on and make corrections. AI algorithms can also monitor production processes and make adjustments to optimize the quality of the final product.

Quality Control In The Food Production Process

AI can play a critical role in ensuring food safety and quality. AI-based inspection systems can detect contaminants, such as foreign objects or harmful bacteria, that may be missed by human inspectors. AI algorithms can also monitor food production processes, ensuring that they meet strict quality and safety standards. Additionally, AI can help to reduce waste and improve efficiency in food production.

Quality Control In The Medical Sector

AI is becoming an increasingly valuable tool in the medical sector, particularly in quality control. AI-based systems can analyze medical images, such as X-rays and CT scans, to identify potential issues and make diagnoses. AI can also help to ensure that medical devices and equipment meet strict quality standards, enhancing patient safety. Additionally, AI can help to optimize medical research and drug development by identifying potential issues early on and streamlining the research process.

Benefits Of Using AI In Quality Control

The use of AI in quality control has become increasingly popular in recent years, and for good reason. AI-powered quality assurance systems can bring multiple benefits, including reduced costs, and increased efficiency. With the ability to automate the testing and inspection process, AI can detect defects and provide valuable insights that help businesses make informed decisions. AI in quality control can also reduce the risk of human error, providing a more accurate and reliable testing process.

Increased Efficiency

AI can enhance the efficiency of quality control processes by automating tasks and reducing the time required to perform them. By automating repetitive tasks, such as data collection and analysis, AI allows QA teams teams to focus on more critical tasks, ultimately improving overall productivity.

Precision And Reliability

AI-based systems can provide highly precise and reliable results, which is critical in quality control. AI algorithms can analyze vast amounts of data and detect patterns and anomalies that may be difficult for humans to detect. This precision and reliability help manufacturers to identify potential quality issues early on, reducing the likelihood of defects or recalls.

Save Time And Resources

By automating tasks and streamlining processes, AI can save time and resources in quality control. This enables manufacturers to conduct quality control processes more efficiently, reducing production time and costs. By identifying potential quality issues early on, manufacturers can avoid costly recalls and other quality-related expenses.

Streamlining Decision-making Processes

AI can help to streamline decision-making processes in quality control by providing valuable insights and recommendations. By analyzing data and identifying potential issues, AI algorithms can provide QA teams with the information they need to make informed decisions quickly. This can help manufacturers to make critical decisions more efficiently, ultimately improving overall quality.

Introduction Of New Methods And Tools

AI can introduce new methods and tools for quality control, ultimately improving the overall quality of products. For example, AI-based inspection systems can detect defects that may be missed by human inspectors, improving the accuracy and consistency of inspections. Additionally, AI can identify areas for improvement and suggest changes that can enhance the overall quality of products.

Prospects For The Development Of Artificial Intelligence In Quality Control

Further Process Automation

As AI technology continues to evolve, we can expect to see further process automation in quality control. This will involve the increased use of AI algorithms to automate tasks such as data collection, analysis, and reporting. This increased automation will allow quality assurance teams to focus on more complex tasks, improving overall efficiency and productivity.

Applying Artificial Intelligence To More Complex Tasks

AI has already proven to be valuable in automating routine tasks in quality control, such as defect detection and analysis. However, as AI technology advances, we can expect to see AI applied to more complex tasks, such as predicting quality issues before they occur. By analyzing large datasets and identifying patterns, AI algorithms can help manufacturers to proactively address quality issues before they arise.

Collaboration Between Humans And Artificial Intelligence In Quality Control

While AI can automate many routine tasks in quality control, human expertise and judgment will continue to be essential. We can expect to see more collaboration between humans and AI in quality control, with AI providing valuable insights and recommendations to human inspectors and analysts. This collaboration can enhance the accuracy and efficiency of quality control processes, ultimately improving the overall quality of products. Additionally, as AI becomes more advanced, we may see humans and AI working together to solve more complex quality assurance challenges.

Six Levels Of AI Testing In Quality Control

AI can help in improving unit testing by automating the process of creating test cases and identifying defects. AI-powered test automation tools can generate test cases automatically based on the code’s behavior and can identify potential defects in the code using techniques such as static code analysis and fuzz testing.

AI can help in improving integration testing by automating the process of integrating different units of code and identifying defects. AI-powered testing tools can automatically create a testing environment, deploy the code, and run tests to identify defects in the integrated system.

AI can help in improving software testing by automating the process of creating test cases and identifying defects. AI-powered testing tools can simulate user behavior and identify potential defects in the system, such as performance bottlenecks and compatibility issues.

AI can help in improving acceptance testing by automating the process of creating test cases and identifying defects. AI-powered testing tools can simulate user scenarios and identify potential defects in the system, such as usability issues and functional errors.

AI can help in improving performance testing by automating the process of creating test cases and identifying performance bottlenecks. AI-powered testing tools can simulate different load conditions and identify potential performance bottlenecks in the system, such as memory leaks and slow response times.

AI tools can help in improving security testing by automating the process of identifying vulnerabilities and weaknesses in the system. AI-powered testing tools can simulate attacks on the system and identify potential security vulnerabilities, such as SQL injection and cross-site scripting.

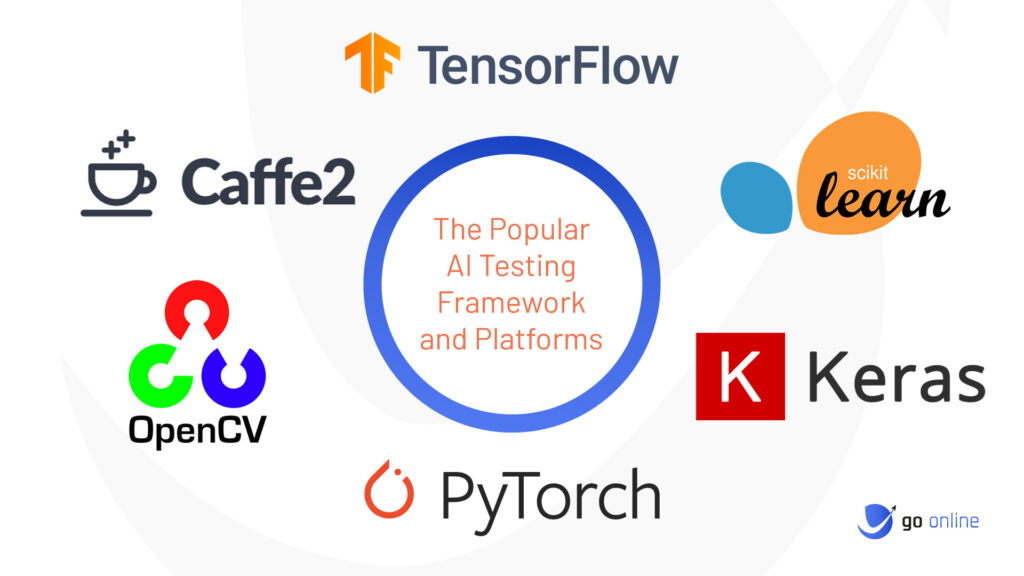

The Popular AI Testing Framework And Platforms

TensorFlow

TensorFlow is a top notch open-source AI testing framework developed by Google. It is widely used in machine learning, deep learning, and natural language processing applications. TensorFlow offers a range of tools and APIs that allow developers to build, test, and deploy AI models efficiently.

PyTorch

PyTorch is an open-source AI testing framework developed by Facebook. It is designed to be flexible and modular, allowing developers to build and test AI models efficiently. PyTorch offers a range of tools and libraries that support machine learning, deep learning, and natural language processing applications.

Keras

Keras is an open-source AI testing framework that provides a high-level interface for building and testing AI models. It is designed to be user-friendly and intuitive, making it easy for developers to build and test models quickly. Keras supports a wide range of AI applications, including computer vision, natural language processing, and predictive analytics.

OpenCV

OpenCV is an open-source AI testing platform designed for computer vision applications. It provides a range of tools and libraries for image and video analysis, including tools for object detection, recognition, and tracking. OpenCV is widely used in industrial and commercial applications, including robotics, security, and surveillance.

Scikit-learn

Scikit-learn is an open-source AI testing platform that provides a range of tools and libraries for machine learning and predictive analytics. It supports a range of algorithms and models, including classification, regression, and clustering. Scikit-learn is widely used in academic and research environments, as well as in commercial applications.

Caffe

Caffe is an open-source AI testing framework designed for deep learning applications. It provides a range of tools and libraries for building and testing deep neural networks, including tools for image and speech recognition, and natural language processing. Caffe is widely used in commercial and industrial applications, including autonomous vehicles, smart cameras, medical imaging, and robotics.

Summary

Artificial intelligence is changing the face of quality control and the prospects for its development are immense. Already, AI powered solutions are being used for data collection, analysis, quality prediction, inspection, and continuous improvement. The benefits of using AI powered solutions in quality control include increased efficiency, precision, reliability, time and resource-saving, streamlining decision-making processes, and the introduction of new methods and tools. There are also several prospects for the development of AI in quality control, such as further process automation, applying AI to more complex tasks, and collaboration between humans and AI. AI testing frameworks and platforms like TensorFlow, PyTorch, and Keras have made it possible to test AI systems in a structured and efficient manner. As AI continues to develop, it will transform quality control even more, leading to new innovations and improvements in the quality of products and services.